Rare Earth Elements

- Home

- Nuclear Technology

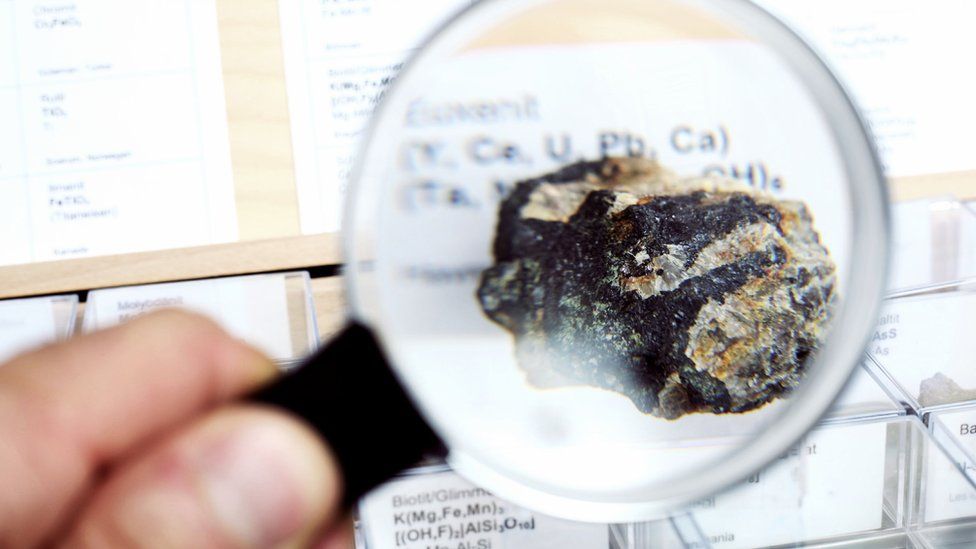

- Rare Earth Elements

Since the studies to evaluate and classify the vast amount of rare earth elements and thorium ores found in Turkey enable the production of the thorium – which can be used at the Molten Salt Reactors –, FİGES continues to offer its contributions, as well as its technological infrastructure by showing no hesitation to take part in the studies to do its share in this field. Thus, FİGES has attended the relevant workshops and working groups organized by the public authorities within this scope as an invitee. Click here for more information.

According to the various scientific research dating back at least 40 years, there are approximately 1,000,000 tons of Rare Earth Elements (REE) and approximately 350,000 tons of thorium (Th) around Eskişehir-Beylikova/Sivrihisar region of Turkey. Another conclusive ore deposit according to the mineralogic and hydrometallurgical studies is located around Burdur-Çanaklı region. This area involves 300,000 tons of REE and 17,000 tons of Th as estimated reserve.

Under the current market conditions, these ore deposits can only be mined and processed via methods based on obtaining the REE. After separation of a concentrate which contains all 15 rare earth elements, it becomes viable to obtain each individual rare earth element with high added value (i.e., Neodymium, Praseodymium, Europium, Samarium, Dysprosium, and Terbium), which can be utilized via precise and advanced technological devices. When REE’s have been separated from the ores, thorium, which always accompanies thereto, can be obtained as a by-product, and stored.

As it is expected to function as an important raw material to generate energy in the near future, thorium should be harvested as a valuable by product of REE production.

FİGES has the knowledge on the processing and separating of both REE and Th ores found in Turkey, thus, the company has been invited to participate in:

- the relevant workshops (Workshop on the Separation of Thorium and Rare Earth Elements, Ege University, Institute of Nuclear Sciences, May 10-11, 2018, Kuşadası, see SCIENTIFIC AN TECHNICAL ACTIVITIES) and

- the Work Study on the Rare Earth Elements and Metals of Refractor Group (Department of Defense Industry, Sub-Study Group Meeting of REE-MRG, September 7, 2018, Ankara)

In the field of processing of REE and Th ores, FİGES will continue to work on plant modelling, and preparation of flow charts for the separation of REE.

Solution Reactor

Within the scope of the R&D and feasibility studies performed for building a prototypical reactor, the researchers have focused on various models to develop a Aqueous Homogenous Reactor (AHR) classified under the Homogenous Reactors, allowing the efficient production of Molybdenum-99 (Mo-99) radioisotope, which attracts great demand in the field of nuclear medicine of our country. Click here for more information.

The “fuel,” which is to invoke a separation reaction in the liquid homogenous reactors, is the “uranyl salt,” composing of maximum 19.75% enriched uranium-235 isotope The “aqueous solution” prepared with this salt easy to dissolve in water is poured into a spherical or cylindrical container after being prepared in mass capable of self-sustaining the nuclear reactions. The temperature emerging during the nuclear separation reaction must be mitigated out of the setting to prevent the solution temperature from exceeding 90°C

Aside from Mo-99, other valuable radioisotopes of the nuclear medicine, such as Xe-133, Sr-89, Y-90, I-131, are among the separation products emerging during the separation of the uranium. During the process, a certain amount of uranyl nitrate solution is extracted and involved in the “chemical cleaning” process to ensure continuous separation of these radioisotopes. The figure below demonstrates the chart of ARGUS Solution Reactor which is operated at the Kurchatov Institute in Russia.

Until now, 30 Solution Reactors, which go back to as far as 45-50 years, have been manufactured. A wide operational knowledge and data is available regarding the operation of these reactors, whose thermal powers range between 0.05 Watt and 5 MWatt.

Based on the calculations, the Solution Reactors are positioned to attract interest once again, thanks to their features such as high Mo-99 production efficiency, low cost, small need for “critical mass,” passive security systems, and simplified fuel processes

International Atomic Energy Agency has also suggested the Solution Reactors as a serious alternative to ensure more efficient use of medical radioisotopes (Mo-99), whose supply has been constrained due to the closure of the expired production reactors around the world, for human health purposes*.

The fact that the manufacturing and design calculations of the Solution Reactors involve codes such as ANSYS CFX 14 is an important driving force for FİGES to assume a leading role in this field.

* IAEA, Production and Supply of Molybdenum-99, Nuclear Technology