SAMOFAR Project

- Home

- Nuclear Technology

- SAMOFAR Project

In the early 2000s, the R&D organizations of some EU-member states reached a consensus on researching new energy generation systems and developing “advanced nuclear reactors” to meet the increased demand for electricity within the EU. Within this scope, at its Grenoble campus, the French National Centre for Scientific Research (CNRS) started to design the “Molten Salt Reactor – MSR,” which is capable of operating at the fast neutron spectrum, processing enriched uranium, actinids, and thorium cycle.

The Molten Salt Reactors are one of the 6 types of 4th generation reactors chosen by the Generation IV International Forum – GIF. The GIF platform was established in 2001 by the founding members, USA, Argentina, Brazil, France, South Korea, United Kingdom, Japan, South Africa, and Canada. In the following years, Switzerland, Euratom, China, and Russia also became members of the organization (see https://www.gen-4.org/gif/jcms/c_9492/members). During the studies performed within the scope of GIF over 130 nuclear reactor designs were examined by over 100 experts in terms of “sustainability,” “economic competitiveness,” “reliability,” “safety,” and “strength against arms race.” As a result of the examinations, 6 types of 4th generation reactors were chosen. Being one of the chosen 6, MSR is the closest technology to be implemented.

Designed by the European countries, MSR system was developed by the consecutive projects funded by the EU. Finally, the “Safety Assessment of MSFR,” or “SAMOFAR” in short, was initiated to focus on the safety of MSR for the 2015-2019 period (http://samofar.eu). Coordinated by Delft Technische Universiteit of the Netherlands, the SAMOFAR project brings several European and non-European organizations together.

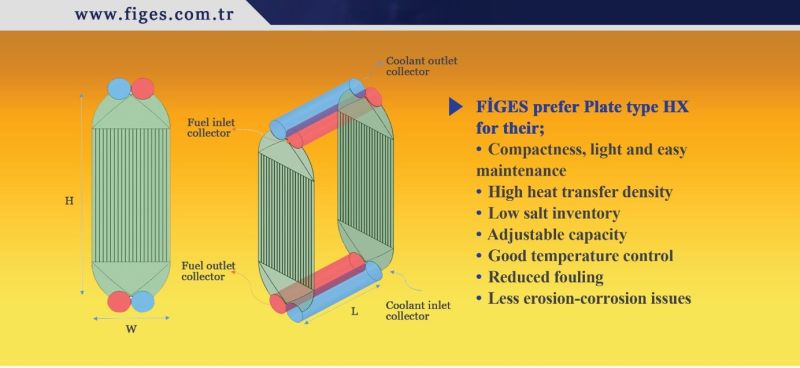

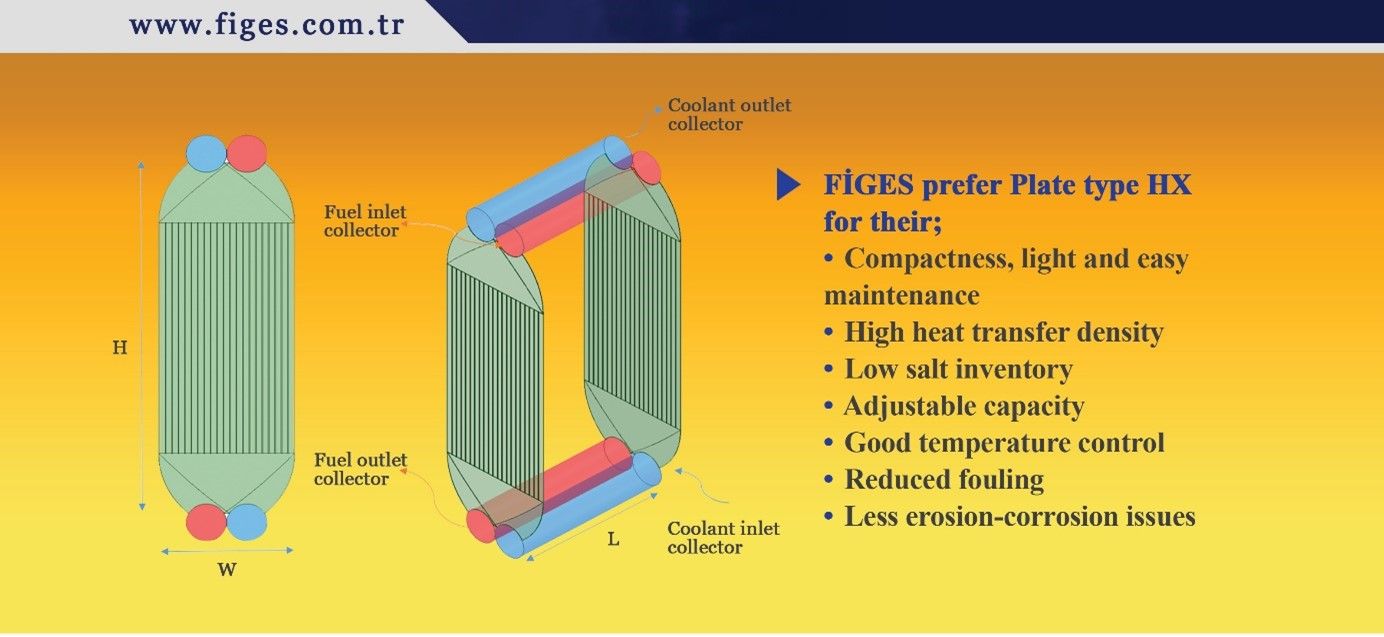

At the end of the negotiations in September 2016, a Confidentiality Agreement was signed by and between the participants of SAMOFAR project and FİGES, whereby the work package involving the design of the primary and secondary heat exchangers of the fast spectrum MSR system was awarded to FİGES. With the same agreement it was agreed that the Scientific and Technological Research Council of Turkey would be a party to the Confidentiality Agreement along with FİGES.

By using the ANSYS software FİGES conducted the calculations and design of the heat exchanges of the Molten Salt Reactors. The heat exchanger design suggested by FİGES was found appropriate by the SAMOFAR consortium.

The results and outputs of the SAMOFAR Project offer great advantages to the developing countries, including Turkey, intending to improve their investments in the nuclear technology, reclaim their independence in the energy production, and invest in the environment-friendly systems.

The indisputable superiority of the Molten Salt Fast Reactor (MSFR), which has emerged as the most advanced and newest design of this prototype with the EU-funded projects, as regards to the currently available conventional nuclear reactors are as follows:

- The MSR is equipped with the most important passive security systems. It will not allow accidents like those happened in Fukushima or Chernobyl because the system does not use high pressure water.

- The MSR is self-secure; as a feature of the system, it automatically stops in case of an emergency with no human intervention.

- The fuel of MSR is liquid (molten salt); therefore, an accident arising from core melting is out of question.

- The MSR allows the use of enriched uranium, nuclear wastes (actinids), and thorium in combination.

- The MSR is particularly suitable for thorium use.

- The MSR can use thorium to generate its own fuel. Thus, thorium resources can be used for thousands of years to come.

- The MSR produces less nuclear waste in terms of both quantity and radioactivity compared to the conventional reactors.

- The efficiency of conversion from heat energy to electricity is near 50% in the MSR (for comparison, this figure is around 35% in the conventional reactors.)

- The MSR is suitable to be operated for high-temperature processing (i.e., chemical industry, hydrogen production, water treatment), and generating electricity.

- The MSR can be built in almost all sizes (micro, small, or large) in a cost-efficient manner.

The heat exchanger unit design suggested by FİGES was found appropriate by the EU-funded SAMOFAR project consortium.